+12

More

Features & Details

- With a 10-ton lifting capacity, our hydraulic press helps you easily disassemble and install car bushings, ball joints, universal joints, and more, as well as straighten, bend, and punch metal parts. Whether you're a professional or an enthusiastic DIY auto repair enthusiast, the press offers quick and easy operation.

- Safety control valve: For safer operation, the hydraulic jack of the hydraulic workshop press is equipped with a safety control valve. If the load pressure exceeds the rated capacity, further lowering is prevented, thus reducing the risk of bending or damage due to overpressure.

- Adjustable Height: The worktable of the hydraulic workshop press features a quick-adjust system with four height settings from 58 to 383 mm (2.3 to 15.1 inches), allowing for flexible working positions. The cylinder stroke is 130 mm (5.1 inches). Note: Exceeding the cylinder stroke range may damage the cylinder seals.

- Stable and wobble-free: The H-shaped door frame structure improves stability and provides a solid base, minimizing wobbling or shaking during component fastening work on the workbench. This design ensures a safer and more reliable working environment and improves the overall precision and efficiency of your work.

- Robust construction: This structure, made of thick steel, offers improved load-bearing capacity and durability. The large-diameter pressure column is designed to minimize slippage and ensure stability and long-lasting performance even under heavy loads.

Frequently Bought Together

Reviews 5.0

All reviews are from verified purchases

Average rating based on 4 reviews

Reviews 5.0

All reviews are from verified purchases

See all 4 reviews

About this item

Product specification

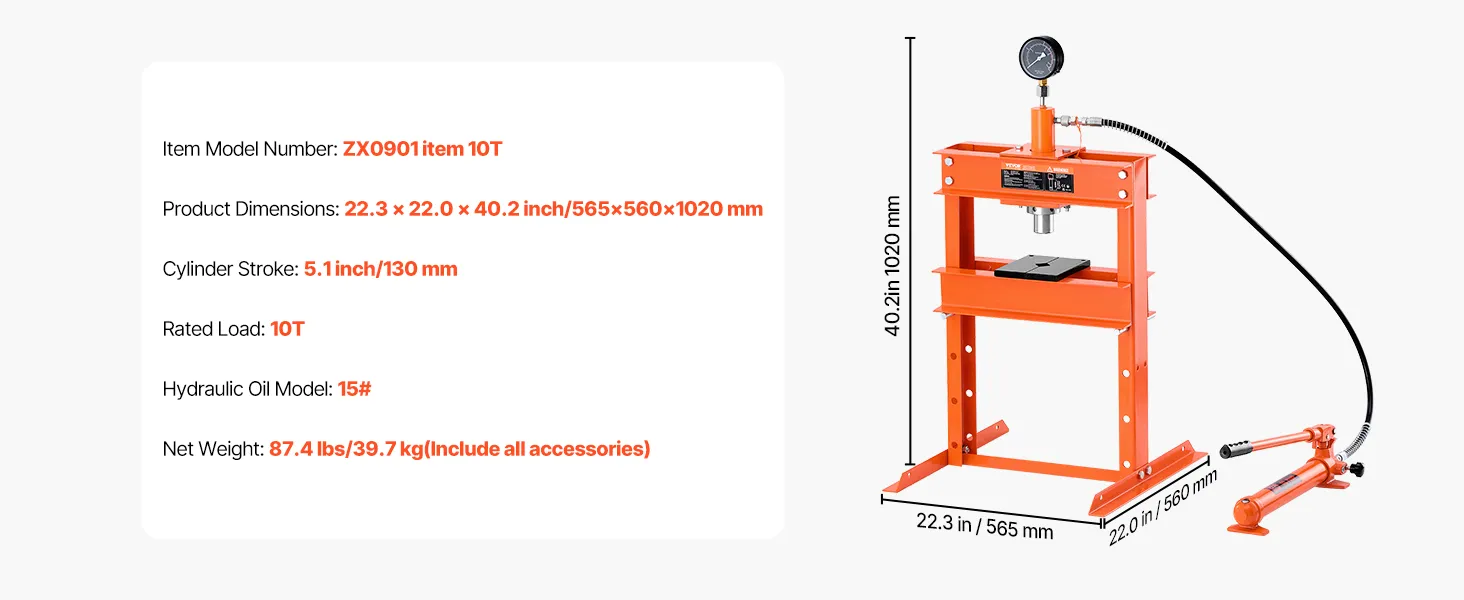

- Item model number

- ZX0901 Item 10T

- Product dimensions

- 30.2 x 23.6 x 69.8 inches / 770 x 596 x 1770 mm

- Cylinder stroke

- 5.1 inches / 130 mm

- Rated load

- 10 t

- Hydraulic oil model

- 15#

- Net weight

- 87.4 lbs / 39.7 kg (including all accessories)

Description

A powerful aid in vehicle repair

Our automotive press is made of high-quality, high-performance steel. This ensures safer and more reliable operation when removing and installing components such as bushings, bearings, ball joints, universal joints, and other parts.

Key Features

Thickened steel

Withstands strong pressure without deformation.

Stable base

Stable and shock-resistant under pressure

Quality assurance

Durable and hard-wearing

Product guides and documents

User manual-de (PDF) Review

Questions and Answers (0)

Typical questions asked about products: Is the product durable? ...

YYYBSQCJYLJTRQRXFV0

VEVOR hydraulic workshop press 10 t (H-frame) with press plate, adjustable hydraulic press (max. cylinder 130 mm) with pressure relief valve, suitable for bending, straightening & punching, orange

5 4 Reviews

295 90 €

Earn at least 2% points on purchases or save up to 15%.

FREE to join

Each when you buy 0+.

Shop

Get -% off for new user

Exclusive 5,00€ off for your first three orders on the App.

Download Now

In Stock

Security & Privacy

100% Secure payment

Secure privacy

FREE Returns

30-day Free Returns

Refund for lost packages / damaged items

Professional Service

12-months warranty

Customer Support